Technical Information

This section gives a description of using insert nut.

And this section continues to update additions in order of customer’s requests.

(Requests are here)

Precautions

1. Jack Out –Torque

Under the below condition, insert nut is coming out.

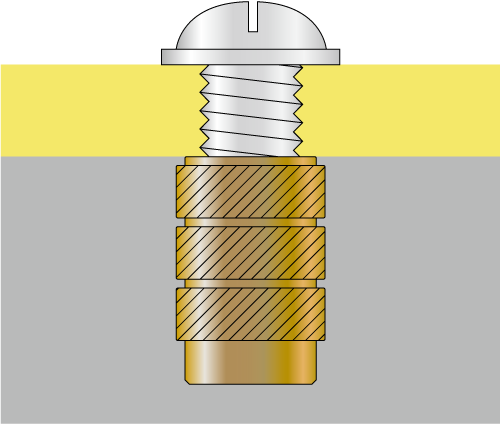

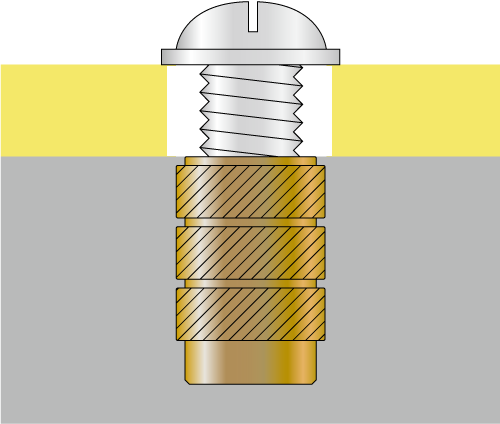

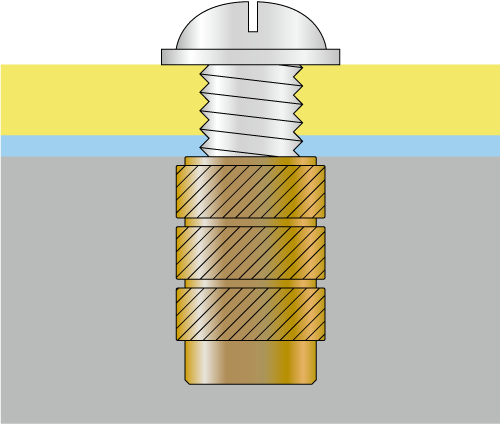

| Status | Schematic Drawing | |

|---|---|---|

| Normal status | The hole of the tightened object is smaller than outer diameter of insert, and the object and insert touches each other. |

|

| Caution required status |

If the hole of the tightened object is larger than outer diameter of insert nut, insert is coming out. |

|

| If soft objects such as robbers are tightened, the insert is coming out. |

|

※Even if the case of the above three figures, it is possible to carry out. If large force is not applied, consider the flange type.

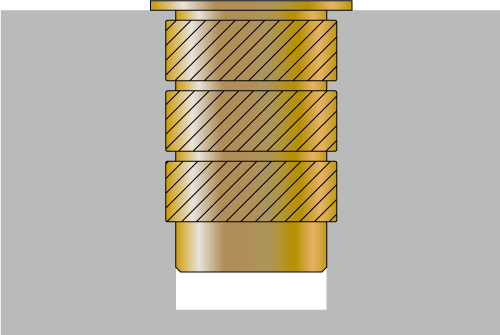

2. Resin hole is too deep.

| When resin hole is too deep, make steps inside the hole or consider flange type such as the right figure. Flange type is available for each after-molding insert. |

|

3. Cautions on inner-diameter of insert

| Inner-diameter of the insert is made along “JISⅡ.” At molding, when pin is used at inner-diameter, follow the below method. 1.Match the pin with the shortest one of “JISⅡ” 2.Contact us about ”Inner-diameter.” |

|

4. Strength of Insert Nut

Strength of insert nut varies with using condition such as inserting method, parental material, hole-diameter of parent material, and shape of parent material.

強About the strength, determine to use after test.

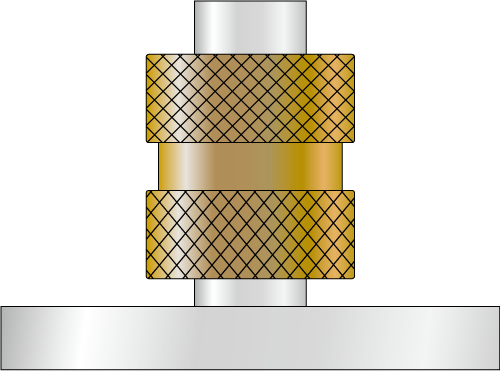

How to Install

As insert nut’s using situation or its purpose has been diverse, how to install has also been diverse.

However, insert nut itself is only two types in a wide range, such as “After-molding insert ” and ”Molding insert.” How to install “after-molding insert” has “expansion method,” ”press fit,” and ”thermocompression.”

And “molding insert” is used in a situation of molding.

1. After-molding Insert

| Method | Features | Products | Image |

|---|---|---|---|

| Expansion |

|

Dodge type SD FD |

|

| Press fit |

|

Bit type SB FB |

|

| Thermocompression |

|

Ultra type UD FD Bit type SB FB |

|

2. Molding Insert

| Method | Features | Products | Imsge |

|---|---|---|---|

| Use at molding |

|

Molding type Parallel Cross |

|

Machining Tolerance・Inner diameter size

1. Tolerance of machining measurement

Without customer’s request, tolerance is made along JIS: middle grade (the 2nd grade.) Details are below.

①Tolerance to the measurement except beveling part.(mm)

| Grade | Standard measurement categories | ||||||

|---|---|---|---|---|---|---|---|

| 0.5≤ ≤3 |

3< ≤6 |

6< ≤30 |

30< ≤120 |

120< ≤400 |

400< ≤1000 |

1000< ≤2000 |

|

| Precise | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| Middle | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| Coarse | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| Very coarse | - | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

②Tolerance to the measurement of beveling part (mm)

| Grade | Standard measurement categories | ||

| 0.5≤ ≤3 |

3< ≤6 |

6< | |

| Precise | ±0.2 | ±0.5 | ±1 |

| Middle | |||

| Coarse | ±0.4 | ±1 | ±2 |

| Very coarse | |||

③Tolerance of the angle measurement (mm)

| Grade | Standard measurement categories | ||||

| ≤10 | 10< ≤50 |

50< ≤120 |

120< ≤400 |

400< | |

| Precise | ±1° | ±30' | ±20' | ±10' | ±5' |

| Middle | |||||

| Coarse | ±1°30' | ±1° | ±30' | ±15' | ±10' |

| Very coarse | ±3° | ±2° | ±1° | ±30' | ±20' |

2. Resin Hole Inner Diameter Measurement

Without customer’s request, tolerance is made along JIS: middle grade (the 2nd grade.)

If the customer dose use the molding insert nut and dose not request inner-diameter, molding pin measurement is refered to "min" on the below table.

Metric parallel-knurling thread

| Thread Size | 2nd grade female-thread inner-diameter | |

|---|---|---|

| max | min | |

| M1×0.25 | 0.785 | 0.729 |

| M1.1×0.25 | 0.885 | 0.829 |

| M1.2×0.25 | 0.985 | 0.929 |

| M1.4×0.3 | 1.142 | 1.075 |

| M1.6×0.35 | 1.321 | 1.221 |

| M1.7×0.35 | 1.421 | 1.321 |

| M1.8×0.35 | 1.521 | 1.421 |

| M2.0×0.4 | 1.679 | 1.567 |

| M2.2×0.45 | 1.839 | 1.713 |

| M2.3×0.4 | 1.979 | 1.867 |

| M2.5×0.45 | 2.138 | 2.013 |

| M2.6×0.45 | 2.238 | 2.113 |

| M3×0.5 | 2.599 | 2.459 |

| ※M3×0.6 | 2.440 | 2.280 |

| M3.5×0.6 | 3.010 | 2.850 |

| M4×0.7 | 3.422 | 3.242 |

| ※M4×0.75 | 3.326 | 3.106 |

| M4.5×0.75 | 3.878 | 3.688 |

| M5×0.8 | 4.334 | 4.134 |

| ※M5×0.9 | 4.170 | 3.930 |

| M6×1.0 | 5.153 | 4.917 |

| M7×1.0 | 6.153 | 5.917 |

| M8×1.25 | 6.912 | 6.647 |

| M9×1.25 | 7.912 | 7.647 |

| M10×1.5 | 8.676 | 8.376 |

| M11×1.5 | 9.676 | 9.376 |

| M12×1.75 | 10.441 | 10.106 |

| M14×2.0 | 12.210 | 11.835 |

| M16×2.0 | 14.210 | 13.835 |

| M18×2.5 | 15.744 | 15.294 |

| M20×2.5 | 17.744 | 17.294 |

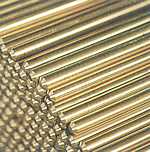

Material of Insert Nut

Without customer’s request, our insert nut is made of brass (C3604BDF)

The below information is confirmed by millsheet at the material receiveing.

Also, since November 2001, earth friendly new alloy → low lead or more anticorrosion material has been used. Free to contact us.

1.Normail material→Brass(C3604BDF)

2.Earth friendly-material→Low lead Brass (BZ5)

1. Brass(C3604)

Material Feature

C3604 is also called Brass, and it is an excellent machinability and ductility. It is widely used, such as bolt, nut, small thread, spindle, gear, valve, lighter, watch, and camera parts. It is currently outstanding to be used as IT equipments or transformation parts.

BDF means B(Bar material), D(Drawing material), F(Fabrication .)

Material Comparison

| Material | ||||

|---|---|---|---|---|

| Brass (C3604) |

Iron (SS400) |

Stainless (SUS304) |

Aluminium (5056) |

|

| Machinability | ○ | △ | × | △ |

| Electric conductivity (% IACS) | ○(26) | △(12) | ×(2) | ○(27) |

| Heat conductivity (W / (m · k) | ○(117) | △(56) | ×(16) | ○(112) |

| No-magnetic | ○ | × | △(depend on treatment) | ○ |

Material Quality

| Contents (by JIS H3250) | |||||

|---|---|---|---|---|---|

| Appearance | Bar is good and uniform finish, there should not be harmful defects at using. | ||||

| Bend | 3mm/2m | ||||

| Chemical Component (%) |

Cu | Pb | Fe | Fe+Sn | Zn |

| 57.0~61.0 | 1.8~3.7 | 0.50以下 | 1.2以下 | Residue | |

| Mechanical & Physical property |

○→required △→N/A |

Tension | Extension | Hardness (Vickers) |

Expired |

| △ | △ | △ | ○ | ||

| 335以上 (N/mm2) |

- | 80以上 (HV) |

H3250 5-5 | ||

2. Lead Free Alloy C6801

Material Quality

1.Chemical Composition (compared to C3604) wt.%

| alloy | Cu | Pb | Fe | Fe+Sn | Bi | Cd | Zn |

|---|---|---|---|---|---|---|---|

| Normal C3604 |

57.0~61.0 | 1.8~3.7 | 0.5以下 | 1.0以下 | - | Unmanaged | alloy |

| C3604 Non Cadomium |

57.0~61.0 | 1.8~3.7 | 0.5以下 | 1.0以下 | - | <75ppm | alloy |

| C6801 | 59.0~60.0 | 0.01以下 | 0.35以下 | 0.6以下 | 2.0~2.4 | 10ppm以下 | alloy |

2. Mechanical Property (compared to C3604)

| Alloy | Quality | Measurement | Tension N/mm2 |

0.2% N/mm2 |

Extension % |

Hardness HV (2/3r) |

|---|---|---|---|---|---|---|

| C3604 | 1/2H | ∅10 | 445 | 320 | 27 | 135 |

| C6801 |

1/2H | ∅10 | 455 | 330 | 25 | 140 |

3. Physical Properties (Compared to C3604)

| Item | Unit | C3604 | C6801 |

|---|---|---|---|

| Specific heat | J/(kg•K) | 377 | 356 |

| Specific gravity |

ー | 8.50 | 8.41 |

| Heat conductivity | W/(m•K) | 117 | 96.4 |

| Liner expansion coefficient | ×10-6/K | 20.5 | 19.6 |

| Young’s modulus | kN/mm2 | 96 | 101 |

| Horizontal elastic modulus | kN/mm2 | 36 | (38) |

| Poisson’s ratio | ー | 0.32 | (0.33) |

| Conductivity | %IACS | 26 | 24 |

| Volume resistivity | ×10-3μΩ•m | 66.3 | 72.4 |

| Heat diffusivity | cm2/sec | 0.365 | 0.322 |

| Impulse wave | J | 36.6 | 24.8 |

※The above date is a measured value, and not guaranteed value.

Plastics Classification

Plastic (resin)is divided into “thermoplastic” & ”thermosetting.”

These resins are clearly differentiated when heat is applied.

The differences are on the below.

Resin differences

| Thermoplastic resin | Softened with applying heat |

| Thermosetting resin | Hardened with applying heat |

Generally, thermoplastic resin is for after-molding insert, and thermosetting resin is for molding insert.

However, there is thermosetting resin for after-molding insert.

Correspondence table and insert plastic

| Resin | Insert | |

|---|---|---|

| Insert | Part No | |

| Thermoplastic | After-molding insert | SB UD SD |

| Thermosetting | Molding insert | SX SH |

| After-molding insert | SD | |

Resin List

| PE |

Polyethylene | ABS | Akurironitoru Styrene Butajinien |

| PP | Polypropylene | PS | Polystyrene |

| PVDC | Polyvinylidene chloride | PMMA | Methyl methacrylate |

| PET | Polyethylene Terefutato |

PVC | Polyvinyl chloride |

| PA | Polyamide | PC | Polycarbonate |

| POM | Polyacetal | PPE | Metamorphic Poriferin Ether |

| PBT | Polybutylene Terefutato |

PSU | Polysulfone |

| GF-PET | GF reinforced polyethylene Terephthalate |

PES | Polyether |

| PPS | Polyphenylene Sulfide |

PAR | Polyarylate |

| PEEK | Polyether Eteruketon |

PAI | Polyamide |

| LCP | Liquid Crystal Polymer | PEI | Polyetherimide |

| PI | Polyimide |

| Phenolic resin | Epoxy resin |

| Urea resin | Diallyl phthalate resin |

| Melamine | Polyurethane |

| Alkyd resins | Silicone resin |

| Unsaturated polyester resin |

How to wash

We insert, free use for our customers at ease, do washing twice for all products before shipment.

The washings are aware of the global environment "hazardous substance" of no use to occur.

Our flow production

Shape Processing |

| ↓ |

Primary washed (Multi-tank solvent washing machine) |

| ↓ |

Complete cleaning (washing machine type water multi-tank) |

| ↓ |

Packaging Shipping |

1. Multi-tank solvent washing machine

| Process Purpose | Washing method | Wash solution |

|---|---|---|

| Degreasing removes chips | Rocking back and forth washed | Industrial washing solvent |

| washed horizontal swing | ||

| Rinse | ||

| Dry | Hot air rotation | ー |

Multi-tank solvent washing machine |

Washing basket |

2 washing machine type water multi-tank

1.Entering the product to the washing basket

2.Set to the washer

3.Fully automatic operations Washing machine type water tank 6

| Process Name | Meaning | Clearing solvent |

|---|---|---|

| Ultrasonic washing | Removal of fat chip removal |

Weak alkaline detergent |

| ↑ |

Rince | Tap water |

| ↑ |

↑ |

↑ |

| Centrifugal separation |

Dry | ー |

| Hot blast blow |

↑ |

ー |

| ↑ |

↑ |

ー |

4.Cooling basket

5.Fetch product

washing machine type water multi-tank |

washing bascket |